|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

|

THE SIMPLEX AUTOMATIC TRACKER is the simplest and most efficient of any of the many devices of this character. It is purely mechanical, has no pneumatics and is operated by a positive constantly active force that operates the music roll. It is the nearest trouble-proof of any tracker we have knowledge of. The four principal parts are the

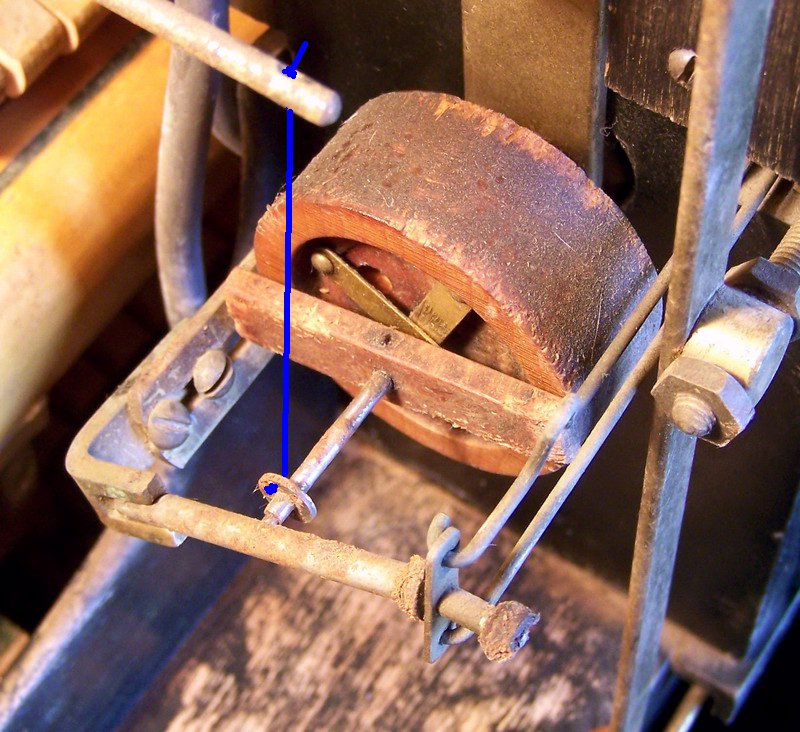

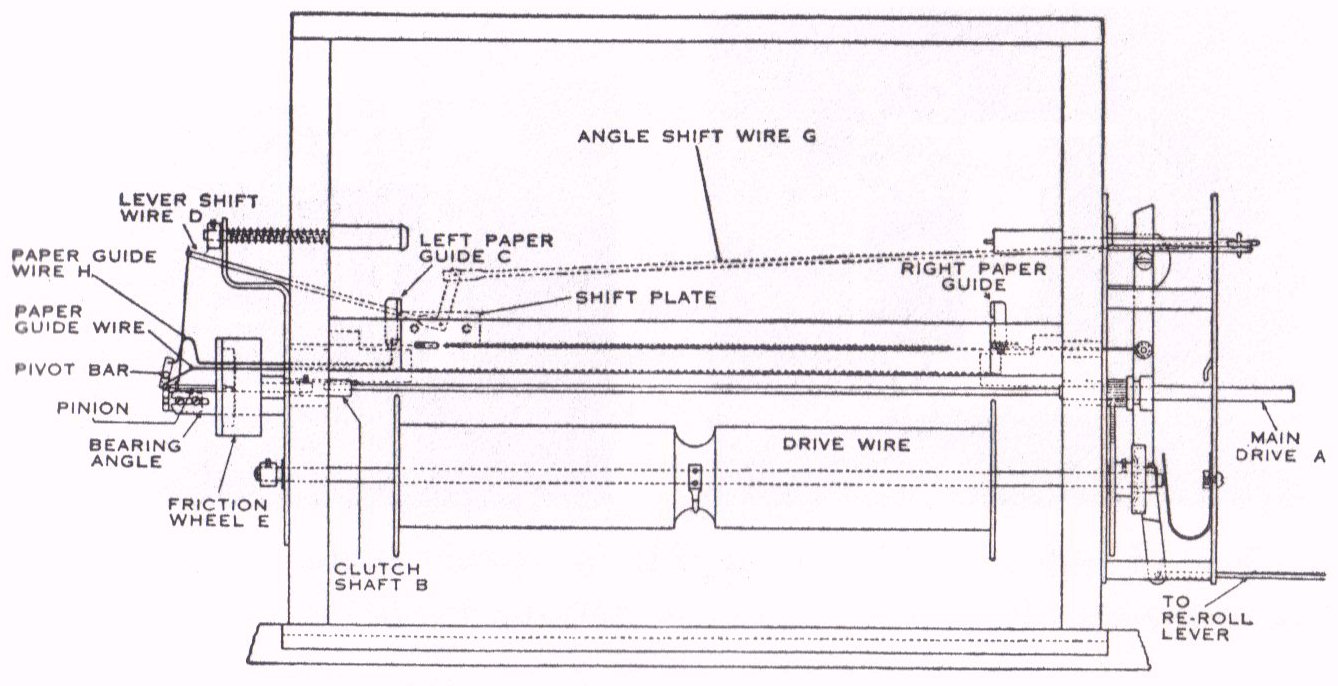

Main drive shaft .......A The main drive is the wire in the center of the gear frame passing under and back of the tracker bar, and is constantly revolved by a chain and sprocket driven by the wind motor. The extension of this shaft through to the left side of spool box is called clutch drive shaft. This shaft is pinned universal joint fashion to main drive shaft and slides back and forth with the main drive shaft for the purpose of connecting the drive shaft to the clutch shaft when playing the roll and to disconnect it in re-rolling. The clutch drive shaft is made up of ten parts; clutch, shaft and bearing, friction wheel, pinion centering plate, spring, pinion bar, pinion, pivot bar, and bearing angle.  (Picture provided by Brian Worden, from his Lexington/Simplex player piano - 8/30/2008) Paper guides are made up of seven parts, right and left guides with two pins, springs, guide wires, also paper guide release wire connected on the gear shifter. Shifter wire is made up of four parts, shift lever angle, shift wire, lever shift wire, transmission cord. The operation of the tracker is as follows: When a roll is being played the drive shaft A is revolving the clutch shaft B at the same time revolving the friction wheel E which in turn revolves the pinion lever, the pinion being pinned to this bar. This bar revolving winds up the cord which is fastened to lever shift wire D and as the cord is wound around the pinion the shift wire is pulled downward which through proper connecting parts causes the music roll to move towards the left. This is brought about only when the right hand edge of the music sheet touches the right side paper guide. When the music roll moves far enough to the left for the left edge of the music sheet to touch the left side paper guide the friction is eliminated between the pinion lever and friction wheel E, and while the friction wheel E continues to revolve in the same direction, the pinion lever will revolve in the reverse direction, allowing the transmission cord to unwind and raise the lever shifter wire arm D and move the music sheet towards the right side through the action of the spring and connecting parts. The result is that after the paper guides are once set in proper location the music sheet when operating alternately touches first one side or the other and is corrected in its location as it gets out of line with tracker first to one side or the other. The cotton cord that connects the lever shifter wire to the pinion is 0.015"-0.018" thick. It must be knotted well enough that the knot will not slip through the holes in the lever shifter wire or the pinion. Below are a few pictures that show how the cord should be knotted.

The easiest way to install the cord is to feed it through the washer near the end of the pinion first. The knot must be on the outermost side of the washer. With the lever shifter wire at its furthest distance from the pinion (or in the uppermost position), feed the cord through the hole in the end of the lever shifter wire and knot the cord as shown above. It is alright to have the cord a little too long, but never too short. Shortening the length of the cord will reduce the range of operation of the tracking mechanism.

If the average roll tracks over to left side, make left side guide wire longer by bending at H and if the roll tracks to the right side too much make the same guide wire shorter by bending at the same place, H. To set the paper shifter, wind the cord around the pinion until almost two-thirds down the full length of the cord and if paper tracks to left, turn buttons in shift wire G to left; if paper tracks to the right, turn buttons to the right. Care should be taken to see that the drive wire A is connected well to clutch shaft B, but not too tight to cause friction. Clutch shaft and pinion should be oiled in its bearings occasionally but put no oil on friction wheel or pinion lever. See that all connecting parts work freely.

Thanks to Gabe Della Fave, I can now list all of the patents issued for the Simplex Tracking Device. They are: December 30, 1913 (1082849); June 22, 1915 (1143684); December 26, 1916 (1210037); June 11, 1918 (1269045); October 1, 1918 (1280319); February 4, 1919 (1293014). Clicking on any of the Patent Numbers will automatically open Adobe Acrobat Reader or Adobe Acrobat (if you have either of them in your computer). [If you don't have the Reader, you can get it free at Adobe -click here.] Below are some of the drawings from the above patents. They are provided to show all of the parts in the system. |

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |