|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

Aeolian Vacuum Pump |

|

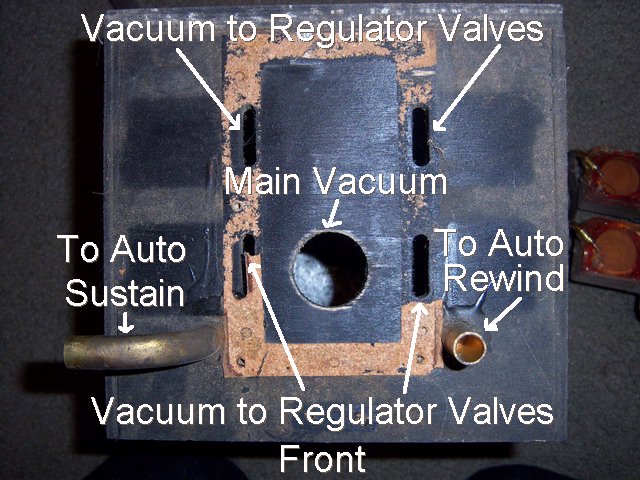

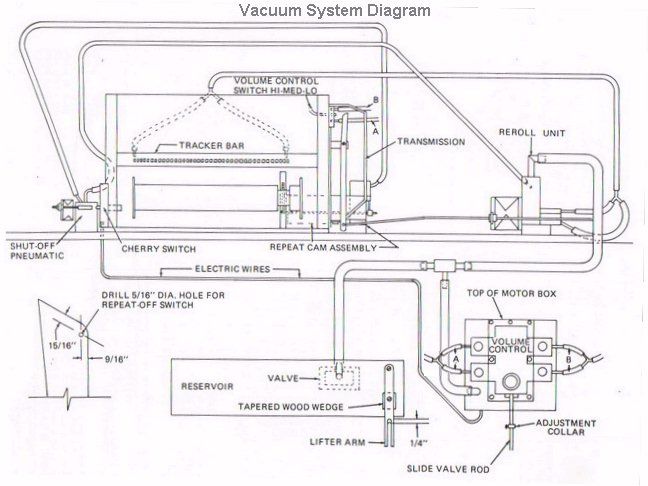

Here are some pictures of the vacuum pump box found in the modern Aeolian player pianos. It should be noted that all of the vacuum pump boxes were not identical. In instruments that did not have an Automatic Sustain, the auxiliary vacuum supply (the elbow) on the left side was connected, via a "T" connector, to the Reroll device. Also, the auxiliary vacuum supply (straight tube) on the right side isn't present. To view and/or save the full size picture, click on the image. For those who aren't familiar with the vacuum system in the modern Aeolian, I have included a diagram from the Aeolian Service Manual at the bottom of this page. |

|

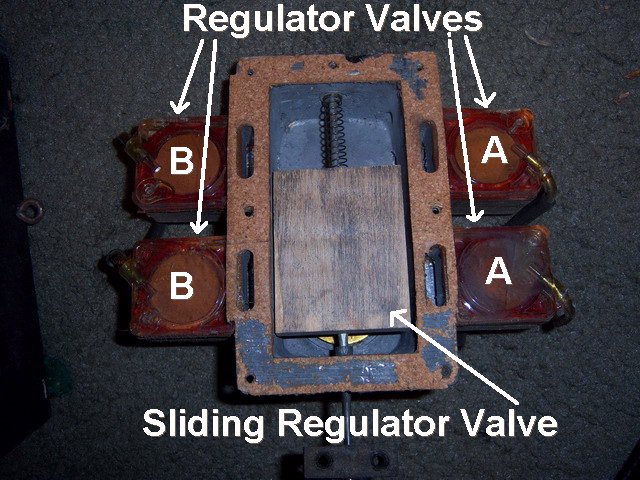

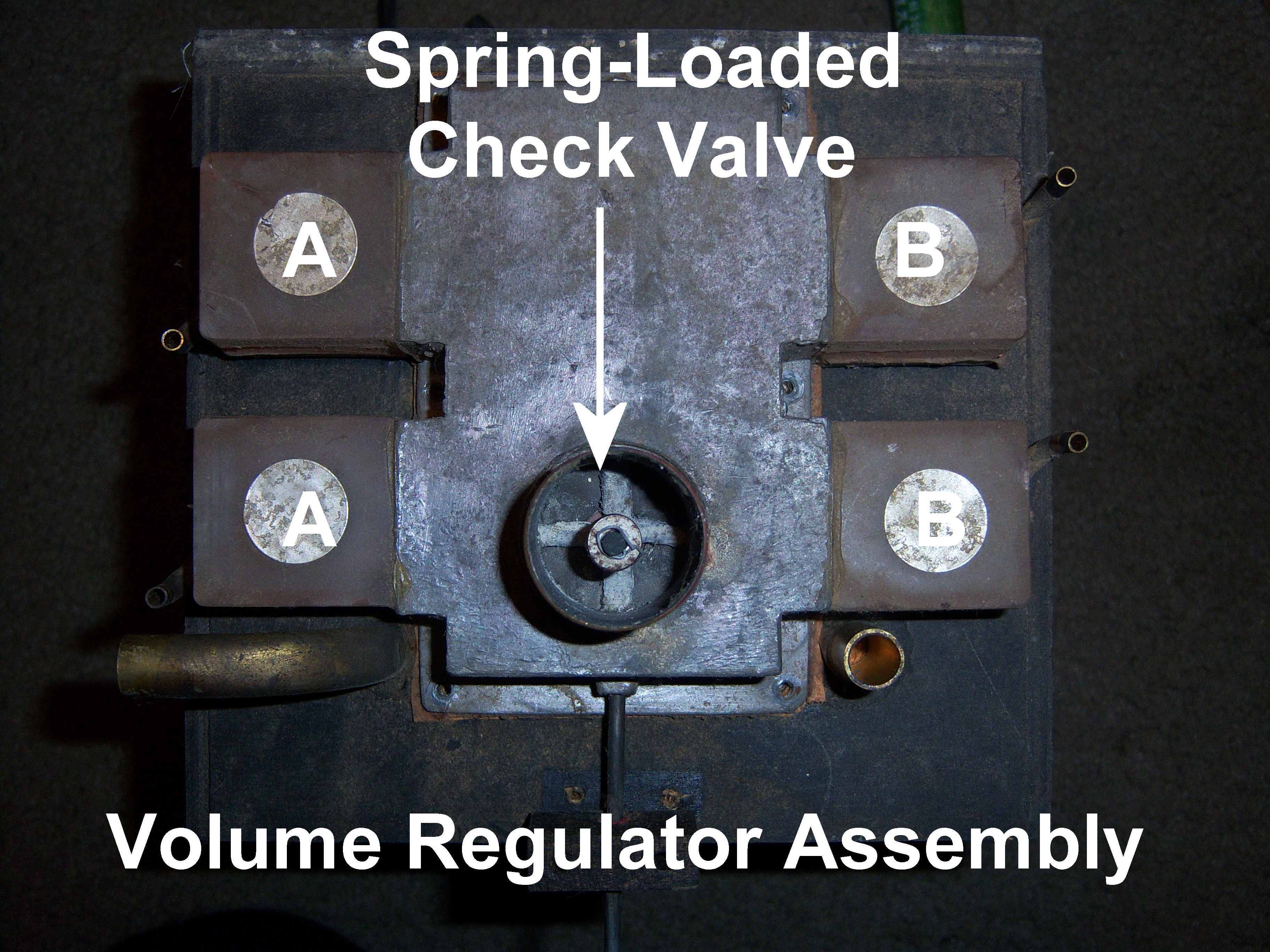

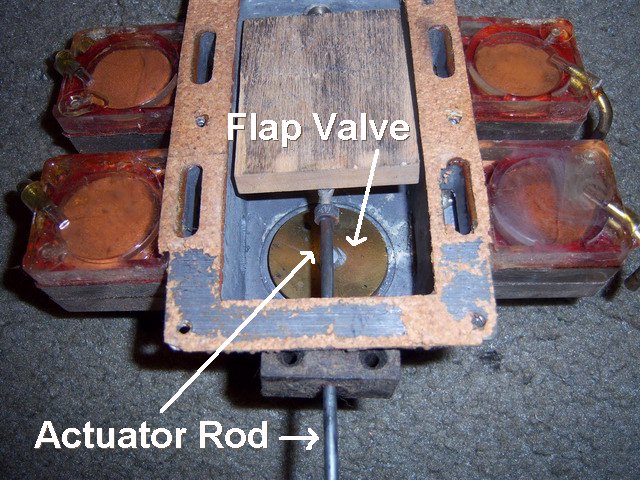

One of the least understood aspects of the Aeolian pump system is the operation of the Volume Control switch. As shown in picture #6, the vacuum from the pump to the reservoir is controlled by the action of the Regulator Valves. When the Volume Switch, in the Spoolbox, is set to 'Lo', all four Regulator Valves are closed. And, the vacuum reaching the Reservoir must pass through the Sliding Regulator Valve. Its relative position is determined by (1) the location of the 'Adjustment Collar' -see picture #7, and (2) the setting of the "Tapered Wooden Wedge" and the "Lifter Arm" -also see picture #7. Together, these adjustments create the 'Minimum Playing Volume', and they should be set such that an aggressive roll will play softly without missing any notes. As the Volume Switch is moved to the 'Med' position, two of the Regulator Valves open which allows some unregulated vacuum to pass through the valves and into the Reservoir at a metered rate. This rate is limited by the size of the port between the vacuum and atmosphere sides of the block valve and the valve clearance, or valve gap -which in most Aeolian block valves is around 0.040"-0.045". Also, since this increase in the vacuum level is both above and below the Sliding Regulator Valve, its operation is in no way hampered, and it will still compensate for changes in vacuum demand. Similarly, when the Volume Switch is set to the 'Hi' position, the other two Regulator Valves open which allows even more unregulated vacuum to bypass the Sliding Regulator Valve.

Another "mystery" concerning the Volume Control Assembly is the circle of silver colored tape that Aeolian put over the exhaust port of each of the four Regulator Valves. These pieces of tape prevent atmosphere from entering into the valve block, but nowhere is their purpose explained in the Aeolian Service Manual or any other technical information ever released by the company. If those pieces of tape are missing or leaking, the regulator cannot work properly. If in doubt, cover the ports with Duct Tape.

So, when Leonard from Washington wrote to me and said, "I have a newer model, Aeolian, 64 key player with electric motor that has some problems. Most of them are related to lack of use, old, and dried out bellows. However, the question I have deals with the volume control located on top of the electric motor unit. The four plastic unit valves on my player have a Mylar covering on the top port of each valve. I have not be able to find any reference to this in the service manual or on your web site. As a matter of fact the service manual and web site describe the valve assemble as having the top port open to outside air. Is this covering required for the volume control assembly or should I remove it?". This web page answers his question.

It didn't take me long to figure out why Aeolian decided to seal the exhaust ports. Below is my reply to Leonard's question.

The question of "WHY?" comes to mind, and

I had to think about that before answering

because it isn't written in any manual or

technical letter. But, it's fairly simple.

The Volume Control in the spoolbox is an

air switch. Although it has only three

positions (Hi-Med-Lo), it can inadvertently

be set at a point where the air holes are

open less than 100%. When that happens, the

associated regulator valves will be in a state of 'half open' or partially open, and

it will allow atmosphere to leak into the

vacuum pump at a very fast rate. (The hole in top of the valve block -or the exhaust port- is 3/8" in diameter. That would constitute a large leak in this system.) That leak

would reduce the vacuum level significantly.

So, Aeolian decided to prevent the possible

problem by sealing the exhaust port permanently.

That way, even if the valve is not fully open

or fully closed, atmosphere can't leak into the

pump. And, if the user (or customer) has a

keen sense concerning the volume of the music,

they can purposely set the switch 'between' the

three volume levels and achieve more control

over the volume.

Thinking about this problem a little deeper, it comes to mind that the absence of the seals creates the possibility of a player system that operates very poorly, or perhaps not at all. Let me explain. If for some reason one or more of the exhaust valve facings in the Regulator Valves were to become contaminated with debris that prevented it from sealing properly, there would be a constant leak in the vacuum system. Also, if any of the rubber tubes that go from the Volume Control switch to the Regulator Valves were to develop a crack or leak, it would act the same as if the Volume Switch were partially open (or closed). Either way, the valve would be in a state of flux, and air could leak into the system.

So, here again, the seals prevent these possible problems from affecting the performance of the player system.

|

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |