|

This article seeks to establish a few basic principles which apply for doing all player valves. Since we are using Ampico block valves for their convenience, and since some people might get kinda critical and say "That's just for Ampico, but my valves are different," I will give them the benefit of the doubt and then invite them to write and tell me how the principles shown here for pouching valves are any different for their brand of valve, despite the poppet or the configuration. That said however, some valves including horizontal valves are made with a metal stems and guides. While their stem travel by design is more mechanically precise, they require a consistent poppet flexibility on those stems for tight seating, so the milliseconds required to fully seat and unseat is at least as long or even greater than for a vertical poppet because the support for the poppet must compress. If, in making the valve poppet flexible also makes it less airtight, then the rebuilder has another problem which he made for himself. When making measurements, especially of actuation sensitivity and speed, if you cannot measure any appreciable differences when making basic changes, then you are either not measuring accurately enough or the differences are not critical to the device. Since operational speeds are very difficult and expensive to measure accurately and not worth the expense of doing it using a scope and actuation measuring devices, and since few rebuilders have those things anyway, I am going to use a more relative approach to make comparisons, which will achieve the same result empirically. All we need is a basis of comparison and exactly identical valves. How do we get identical valves then, you ask? Wait just a minute, and you'll find out. Just remember, we can be diabolical, too! |

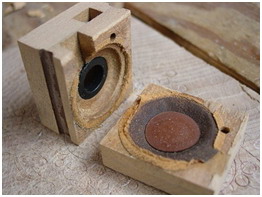

Fine white pouch leather measuring .009" thick. This sample will be one of the two types of pouch leather used for this demonstration. |

Low valve mass and low friction is important especially for good repetition. The heavier the valve, the larger the pouch required as well. Also the larger the seating area of a valve, the more power is required by the pouch to unseat it. For instance, the difference to unseat a 3/4" dia. poppet versus a 5/8" dia. poppet is about 44%. Granted, Ampico used both poppets in their block valves with the same size pouch, but the only noticeable advantage of the larger poppet would be possibly in operating the damper pedal, and they seldom used them for that purpose. |

|

The difference in actuation speed (up travel time) of a valve is less important since the typical inside valve (secondary valve) is about 4 times faster to actuate than to return (down travel time), so its repetition speed hinges not on speed of actuation as many assume, but on reseating time. Therefore, the larger poppet might, theoretically speaking, be faster overall as long as the additional pouch resistance doesn't exceed 50%. This tells me that Ampico had a good knowledge of this variable since it is found in the evolution of the device. It costs a company a lot of money to make a fundamental change like poppet design and its inside valve seat, for no other reason than a whim. |

|

Curiously though, both poppet sizes are found in the Ampico model B valve, which tells me that the difference wasn't substantial enough to standardize the change, so they had lots of poppets and plastic seats already made. At the same time, Aeolian took over manufacture, so let's factor that in as well and it becomes a curious observation. I have restored many Ampicos of both models, each using both valve poppet sizes and cannot tell any substantial differences, so either size is easily within parameters and therefore will not make performance changes. The thing that makes the most change in valve performance tends to be the hopeful imagination of the rebuilder. What we hope to do here is factor that out of our equation. |

Soft tan pouch leather shown doubled. But the |

|

The larger the pouch, the slower the valve. But when you speak of valve speed (repetition speed) you are not talking about taxing any note valve that I'm aware of. A good valve can repeat many times faster than any piano note I'm familiar with. So when you have a repetition capability that is several times greater than the speed that any musician can repeat a piano note, or a banjo for that matter, then response time is never a limiting factor. But we run into problems incurred with things like grand drawers, where the distance between the tracker bar and the valve stretches the limit of pneumatic sensitivity at very low pressure. Those tubes can measure almost 6 ft. in length. The Ampico therefore would be the perfect system to test valve sensitivity and repetition with because there can be almost six feet of small tubing in some cases between the tracker bar and the valve. No other player system except player drawer grands whose stacks are behind their drawer compete with those same drawbacks. The nickel pianos and standard uprights didn't have this problem because they were not required to play reliably at the extremely low vacuum levels of a reproducing piano, nor did they have an extreme layout configuration to overcome. They were designed for musically uncritical pop-commercial enjoyment. |

Ampico B block with oil of some kind. |

This has been a point of contention for decades, but let's cut to the chase. Did Ampico seal their pouches? Yes they did. They used rubber cement and talc. We are talking about the most difficult system to make work in the industry. Later, with the Ampico model B, they were able to do away with the primary valves by using a ball bleed valve. This is a check valve that allowed a single valve to operate initially on a #70 fixed bleed, and drop again with the #56 plus the #70. That made it very fast, and they did that by allowing the bleed size to change. Proof that sealing the pouch was primary since pouch leakage can easily equal or surpass several regular-sized fixed bleeds. |

|

That said, Duo-Art also sealed their pouches but they used either a gelatin or nitrocellulose. Since they didn't use drawers in most of their instruments (until the late 30's), pouch sealing wasn't as necessary in a Duo-Art, but seaweed gelatin was more likely their sealant of choice for valves. This gelatin was also used by the case finishing departments in many companies, could be dissolved in alcohol, and was readily available on the market. Victor Talking Machine Co. used it to seal their case wood before finishing and it's possible that piano companies did it the same way, although lacquer (nitrocellulose) was used for accordions on the Duo-Art expression boxes. Regardless, all reproducing pianos had sealed pouches and leather. You will find out why this was a necessity, not an "option." Pouch leather of the time was tanned from registered herds of specially grown Scottish Highland sheep, raised for just that purpose. When the Ampico B was designed, it was designed around pouch leather that measured between .005 and .007" thick. It is almost impossible today to buy leather that thin, without tiny holes in it. So today we must select sections out of several skins which represent their thinnest and most supple without flaws, and punch out only that portion. A factory couldn't afford to do that, today. Uniformly thin leather was necessary to quickly inspect the skins mark, and trim bad places out before sealing it. They would then talc the leather and punch it out. The problem with using rubber cement to seal pouches AFTER they are laid is pretty obvious. The cement takes a set in the shape of a bowl and then over time, it hardens that way, with the thickest portion of sealant around the rim of the pouch well. So while all sealants will stiffen the pouch slightly, rubber cement stiffens it exactly where you don't want it to be stiff! |

which are unsuitable for pouches, but other areas are just fine. You must select your leather in the skin itself. |

But there are other reasons not to use office supply rubber cement. In olden times, rubber cement was formulated to last longer. Today, it's barely used at all, except for kindergarten crafts and little stuff like that. It gets hard and stiff quickly, and in 10 years or less, has turned into a powder. Elmer's and Best Test are two good examples of the very temporary nature of modern rubber cement. If you would like to try a good grade of rubber cement, you might shop here. They carry rubber cement designed to repair shoes. http://www.wardrobesupplies.com/categories/shoe-care/more/shoe-adhesives |

|

If pouch leather is supple and tight in relation to its bleed size, there may be no reason to use sealer, when rebuilding regular players and coin pianos, since air-tightness is relative to the ideal bleed. But when it comes to reproducers, and particularly those with grand drawers, there is just no way around using a sealer on valve pouches. It must be done, as will be demonstrated shortly.

Any leather sealer must do two things, today. It must be able to seal pouch leather from leakage, and it must preserve the leather and protect it from deterioration. Bacteria and mold both attack leather, so whatever is used must be totally inert if possible. Animal and mineral oils are not leather preservatives, regardless what it says on the can, and stuff like neatsfoot oil (which today is adulterated) will destroy leather in short order, nor does it make it airtight, except temporarily. Oil both evaporates and spreads out. Oil doesn't like microscopic holes to fill. It prefers more support, so while it was filling the pores right after you applied it, it quickly moves into the leather fiber itself where the leather is the thickest. Don't waste another piano testing this out. It's already been done. Oiling boots to make them waterproof is a good idea because it increases surface tension, which repels water and keeps them dry, not because it makes them airtight. If boots became airtight, nobody would use that stuff because their feet would sweat. So just keep these basics in mind. We've also covered ordinary rubber cement, but all cements stiffen leather. It will stiffen the leather to a lesser degree if applied to the leather goods first, before it's punched. There may be some synthetic polymers out there that seal well also. Not all cements are latex, but because of the stiffening factor, the loss of suppleness could be far more detrimental than the tightness achieved, so the thing to do when experimenting is to build a test stand and try it first, just like you will see here. Don't do anything by guessing. Test first. "Test. Don't Guess." Try it out first. |

|

I started using Dow Corning Pure Silicone Grease #111 many decades ago and have yet today never seen its equal. Most people think of it as grease. It is not. Thin it first in something like lacquer thinner (see NOTE) and it will not only preserve the leather but will seal it too with a very minimum of stiffening, if at all. It is the only sealer I know of that I cannot find any fault with and it lasts forever. Nor does it migrate to thicker leather like oils do, nor does it evaporate over time like all other oils do. |

Two leathers compared. The white is stiffer but both are |

|

Dow 111 Silicone is used in deep space where the air pressure is zero. Were vapor pressure losses a problem with silicone like ordinary oil and grease it would never work but the fact is, silicone is not really a grease. It just has lubricity like grease. Look it up: https://en.wikipedia.org/wiki/Silicone_grease. It's a polysiloxane whose thickener is silica. That would make it a kissin' cousin to sand. No self-respecting bacterium or mold is ever going to touch it, and it's never going away. So when you thin with lacquer thinner (see NOTE), you not only kill the bacteria the leather came with, but you protect it somewhat from further deterioration, probably better than anything else you could ever use. |

|

We interviewed some pretty ugly bacteria yesterday and when we said silica, all we heard was "Oh Yuck!" (Italics my own. It really wasn't much of an interview come to think of it, but pretty sure that wasn't referring to the color). I know what you're thinking; "How could you joke at a time like this? Bacteria have rights, too. What are they going to eat?" (Or, maybe not!) |

|

right. Note ?" leather spot ready to receive lifter disk. |

When it comes to thinning the silicone grease, some might ask "how thin?" But this is a matter I will leave up to you because I do it by decades of experience only. I then talc the pouches, and I don't need to seal the leather in the skin first, which allows me to use hot hide glue to install the pouch, plus add a lifter disk as required. In this picture we begin with unsealed pouches. The white leather seems to be the tightest grain, but testing shows it to be very porous, even though there were no pinholes anywhere in the skin, and the texture was the smoothest among both samples. The finished side was actually glossy. |

|

Remember too that the white leather was naturally stiffer than the tan. Usually, stiffer leather is expected to be more airtight, but this didn't seem to be the case. I suspect the white leather was rolled under heavy pressure to compress and stretch it. However that's just guessing. I don't know how it's made. I can say for sure their processing did not make it more airtight. To eliminate any possibility of valve or poppet differences which would skew our results, we've designed our test to be performed equally with interchangeable blocks for the pouch boards. The boards are banded tightly to the block and then tested for sensitivity at a fixed vacuum level. |

|

|

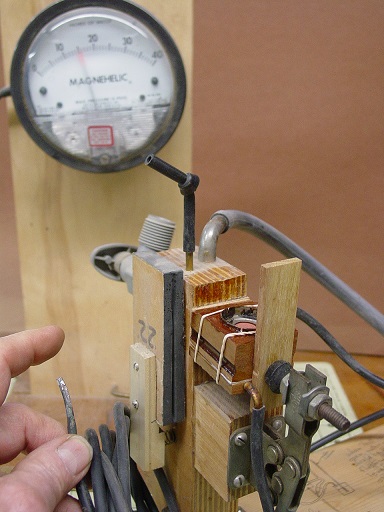

We completely eliminated any possibility for variance between valve blocks and poppets by operating both valve blocks in turn at exactly the same regulated pressure from a rotary positive displacement player pump and regulator with each pouch block. Since there was no differences between the valves that we could measure, this factor was eliminated but it was the only way to eliminate any doubts as to the chances of unknown variables between valve poppets spoiling the results. So when you see the results, know that each one included the switching of valve blocks and retesting to possibly find any differences. The vacuum source is a rebuilt Duo-Art pump, by the way. Its regulator was adjusted to a variance between 3" H2O and 40" H2O for this test. This is checked by a Magnahelic vacuum/pressure gauge. The picture on the left shows the test pneumatic finally pulling closed with a supply vacuum at 35" for an unsealed white leather pouch trying to operate with 10.5 ft. or tracker bar tubing. That is extremely high. |

|

The reason for such insensitivity was not yet apparent, so we switched valve blocks and tried it again, raising the vacuum gradually, as it was done the first time. When the gauge was very close to 35", the pneumatic again closed. Repeated testing never allowed this pouch to show temporary improvement or variance and the reason was the long tracker bar tube, because when the tube was shortened to 3 ft. the valve easily operated every time, reliably at 10". Now you might also think that wasn't very good, either. So let's switch now to the tan pouch leather. I too was surprised at how badly the white leather seemed to perform. Remember too that I never checked the leather for natural porosity, only for pinholes. Neither sample had any visible pinholes, which can be easily checked against a window, somewhere. |

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 |