|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

| Below is an email from Gaylan Lang about a fairly common problem in older player pianos. In an effort to help other people solve this annoying problem by themselves, I created this web page. The information below is primarily related to player systems with one set of note valves. However, I have included a short paragraph at the end about a similar problem in a double-valve system.... Signed: John A.Tuttle |

At 09:59 PM 1/11/04, you wrote: John, thank you in advance for taking a moment to acknowledge my inquiry. I have a Lakeside upright player piano that our tuner told us was built in approximately 1918. Twelve of the eighty-eight keys draw down as soon as we begin to operate the foot bellows. I enjoy doing many types of repairs myself. I have removed the player from the piano as to be able to work on it. Upon visual inspection, I do not see any difference in the small bellows that draw down from those that remain in their positions ready to react when they are supposed to. I will appreciate if you could give a brief explanation of what might be the cause and how the repair would be done. I live in Aberdeen, South Dakota and will be happy to purchase repair parts from you. My email is gaylanlang@netscape.net Thanks again, Gaylan Lang

Another response to a customer: Notes that stay 'On' have one (or more) of five problems. 1. A piece of debris is stuck between the intake valve facing and the intake valve seat. It cannot be removed by using a trackerbar pump. But, sometimes it can be dislodged by collapsing the bellows when there is no vacuum applied to the stack. Also, it can sometimes be dislodged by turning the valve around manually with a needle (if you can access the exhaust port). The problem here is that the valve cannot seat properly, and vacuum leaks around the bad seat, activating the bellows (or sucking the air out -and causing it to collapse). 2. There is a leak somewhere in the line (or tube) between the trackerbar and the pouch. Since I smoke, I generally find such leaks by blowing smoke in the hole on the trackerbar for that particular note and have someone else watch to see if the smoke comes out somewhere. Other than that method, you have to dismantle the stack and check each segment of the line between the trackerbar and the pouch. Any leak in the line is seen by the pouch as a signal to activate the pouch and open the valve -and in turn activate (or collapse) the bellow. 3. There is insufficient clearance between the pouch and the valve button, making it impossible for the valve to seat. Here again, as in Problem 1, the vacuum leaks around the intake valve facing and sucks the bellows closed. 4. The intake valve facing is defective, and vacuum is leaking around the seal between the facing and the valve stem. Fixing that problem requires the replacement of the valve facing. 5. There is a crack in the windchest which is allowing vacuum to suck the air out of the bellow. Finding that problem can be quite daunting, and it always requires dismantling the chest. thanks for this information John, I am actually working on this problem now. I am using a automotive light duty vacuum clean which pulls around 10" wc and have put a hose on the intake side of the stack and covered all of the tracker bar holes and as soon as I hook it up I see the problem bellows compress. If I uncover the hole in the tracker bar that represents the bellows that is compressed I see a slight amount of movement in that bellow. If I pull the front cover off of the front of the stack (which exposes the valves on my model) how do I know which valve cooresponds to the right bellow? Should I unscrew the two screws which hold the valve in place? and attempt to clear the debris this way? below is my style of valves. Also, all of the pouches look good, there is no obvious signs of a valve problem so I suspect that either the valve is not seating properly or there is debris behind it.

You have to count the note holes from the right and left and compare the number with the number of note valves in the chest. I usually do it by physical examination -comparing the location of the first note valve to the location of the first note hole on the trackerbar. It can also be done by the location of the bellows itself. i.e., top tier, middle tier, bottom tier. Then position of the bellows from the breaks in the piano action, i.e. tenor break, and treble break (or tenor, treble, and high treble -if there are four sections in the piano action). Removing the valve plate and examining the valve itself is a good idea. You might even remove the one next to the bad one to compare the two, and see why one is good and one is bad. However, based on what you said about the way the bellows acted when you physically uncovered the note hole in the trackerbar, I'm more inclined to think that there's a leak in the line from the trackerbar to the pouch.... Hi John, I think I just found my problem - I pulled off the cover to the valves. the problem bellows was on the top row. I counted the number of bellows on the top row until I got to the problem bellow. I then went to the opposite side and counted in the same direction the number of valves. I pulled off the valve and found that the leather valve face was loose on the valve stem. Because I was not certain if it was supposed to float on the stem I check two more by pulling them off and found that the valve face was snug on the valve stem. So I think my next step is to glue the valve face (leather looking washer) back on the valve stem. Thoughts?

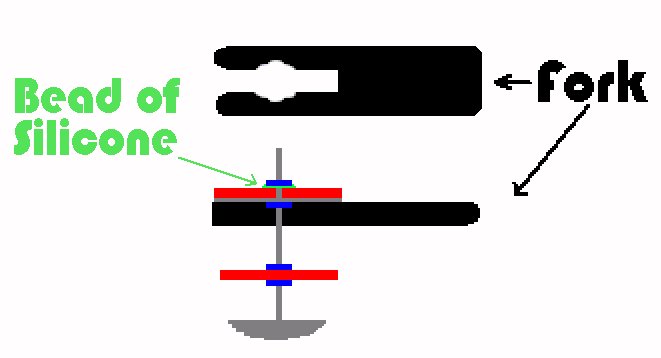

Naturally, the right thing to do is to replace the valve facing with a new valve facing. But, a temporary fix is to use clear silicon caulking and draw a very thin bead around the brass collar, and then press the valve facing up against the collar, then let it dry in an upside down position, supporting the valve facing on a type of fork, so the weight of the valve holds the facing to the collar. (see simple diagram)

good morning John, I just reassembled the action and reinstalled it, and guess what? It works now! No more activated key... I should add this to my list of items to purchase. I think I saw that you had these for sale on your website, I will verify. Thanks again for you help!

Actually, I sell Phenoseal at the site, and it can be used in the same fashion.. but more easily. The industry 'blackballs' me for giving such advice, but when it makes such a huge difference in performance and doesn't cost more than a few bucks, I leave it to the customer to decide if it's worthwhile. The cost of a complete valve job is generally over $2000.... Below is a picture of the squeeze bottle as compared to a standard lighter.

|

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |