|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

"Dismantling the |

|

After spending a number of hours trying various techniques to dismantle these blocks without causing any damage, it was found that steaming them apart is by far the most efficient method. Here's a video that shows the whole process.

More information about rebuilding these block valves is still being put together as of 10-1-2015, but here are some pictures that should give you a pretty clear idea of how the valve gets assembled. A kit may be available at some time in the future. Details are still being worked out.

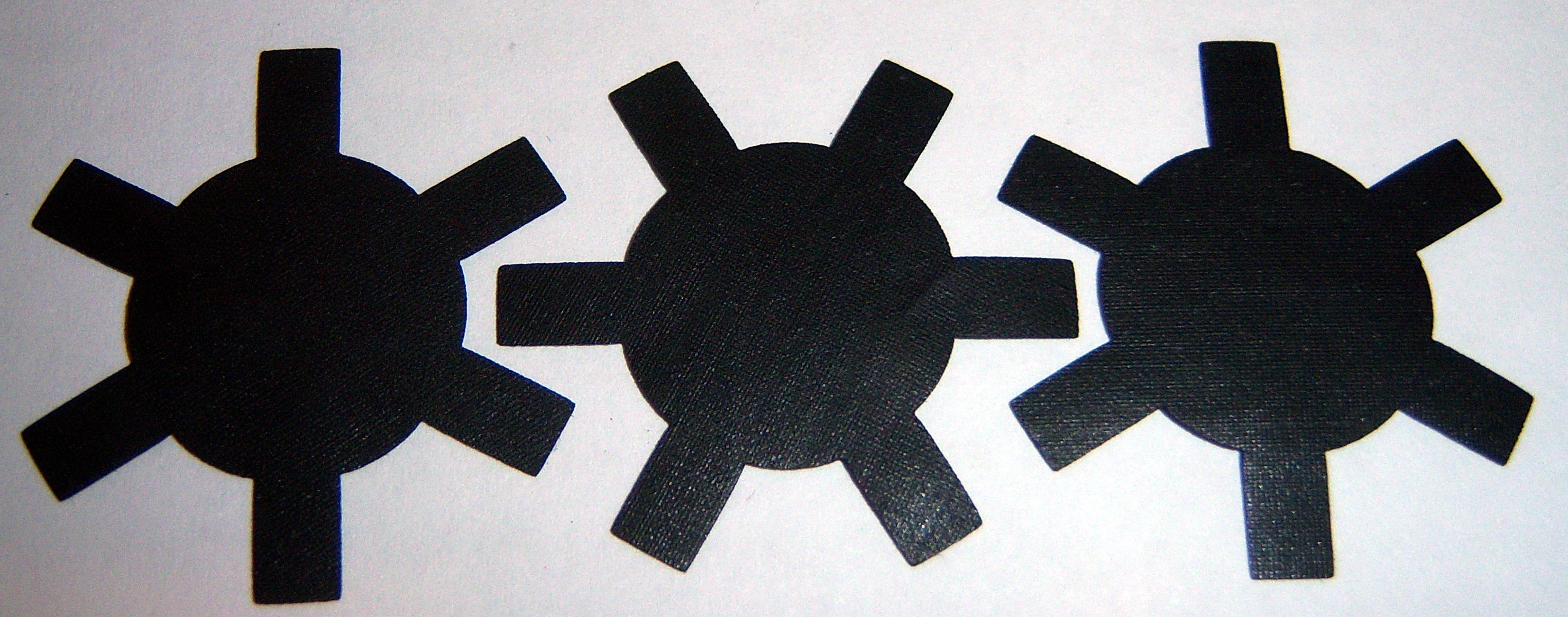

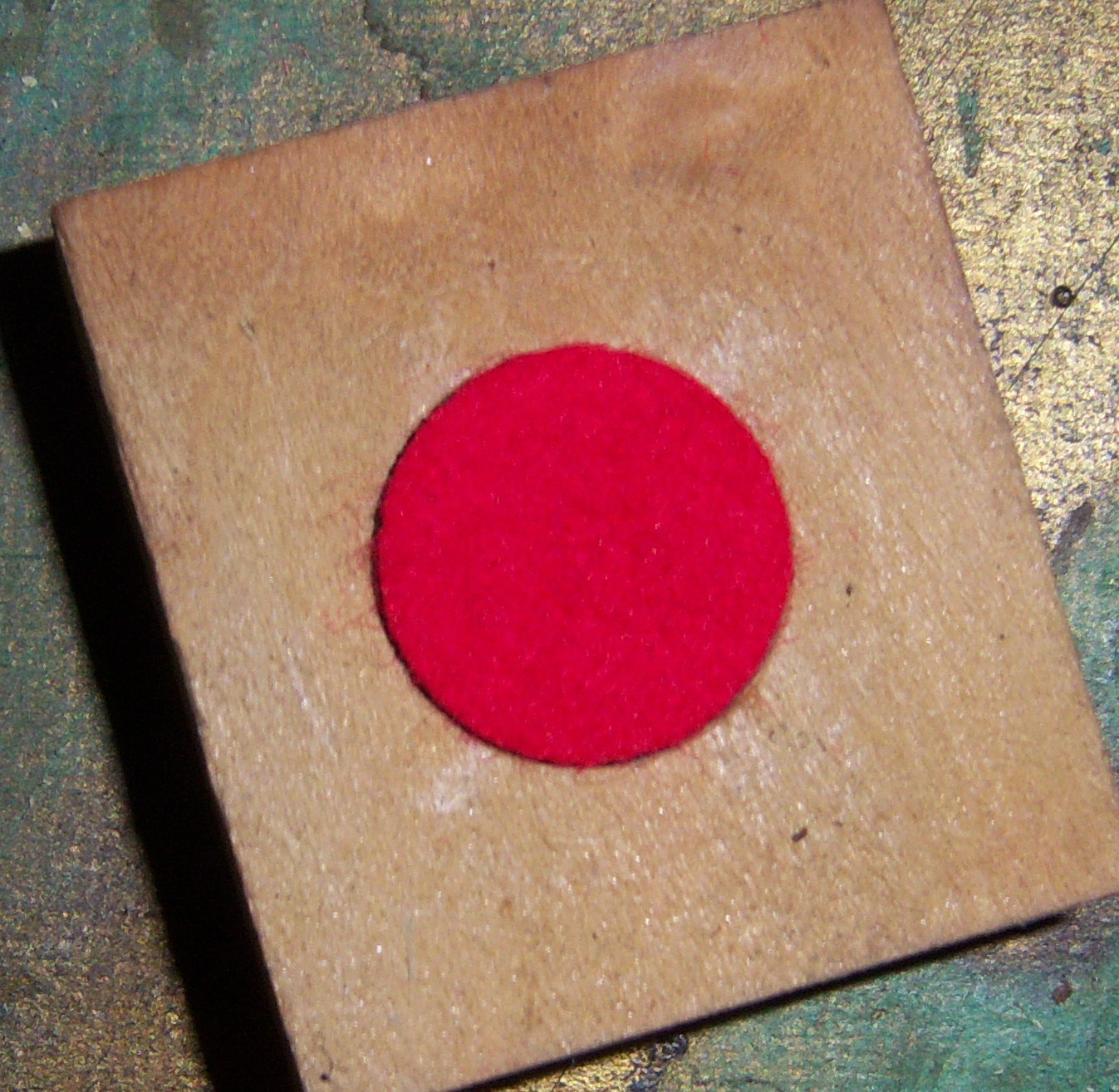

The new valve facings

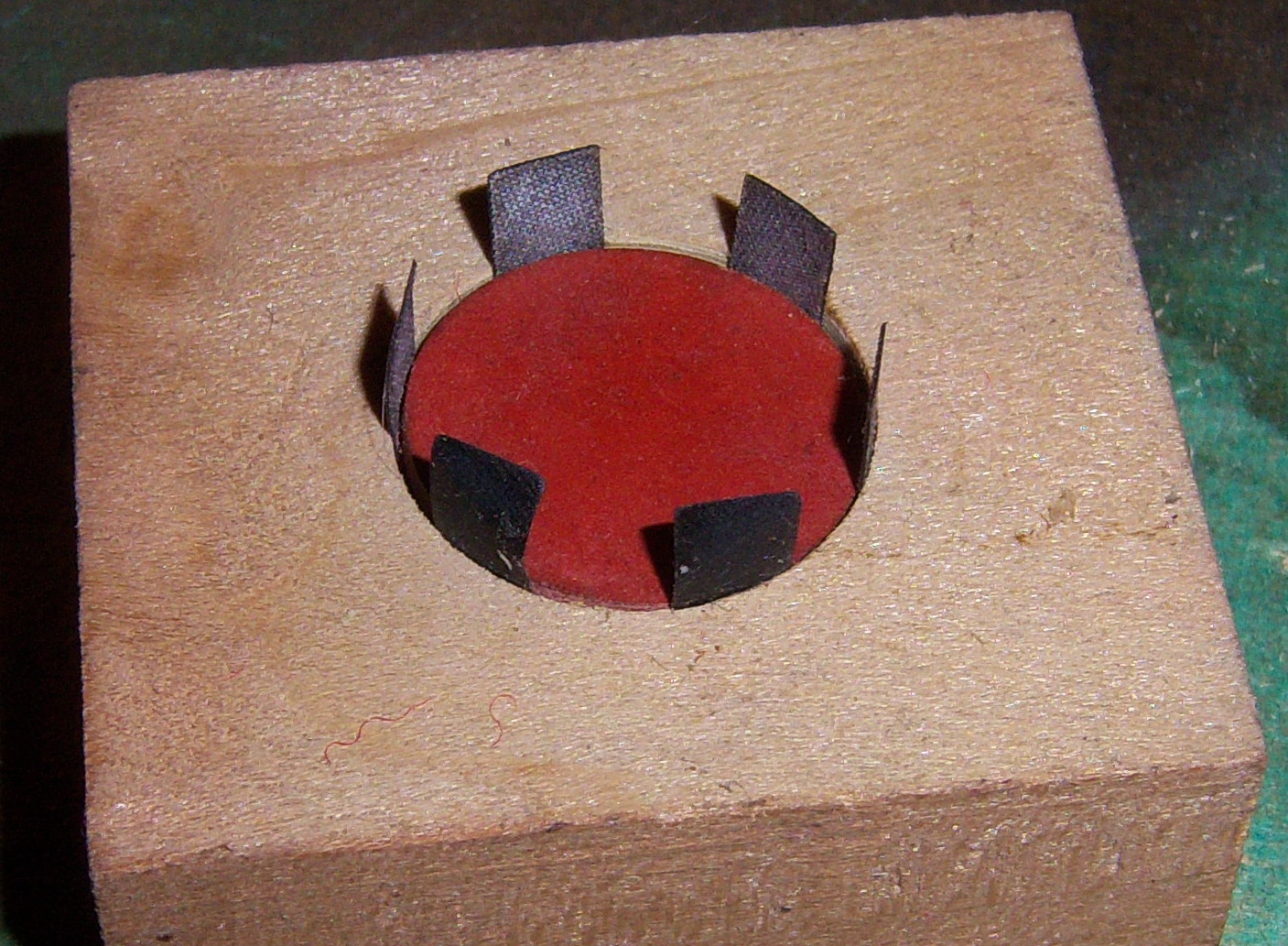

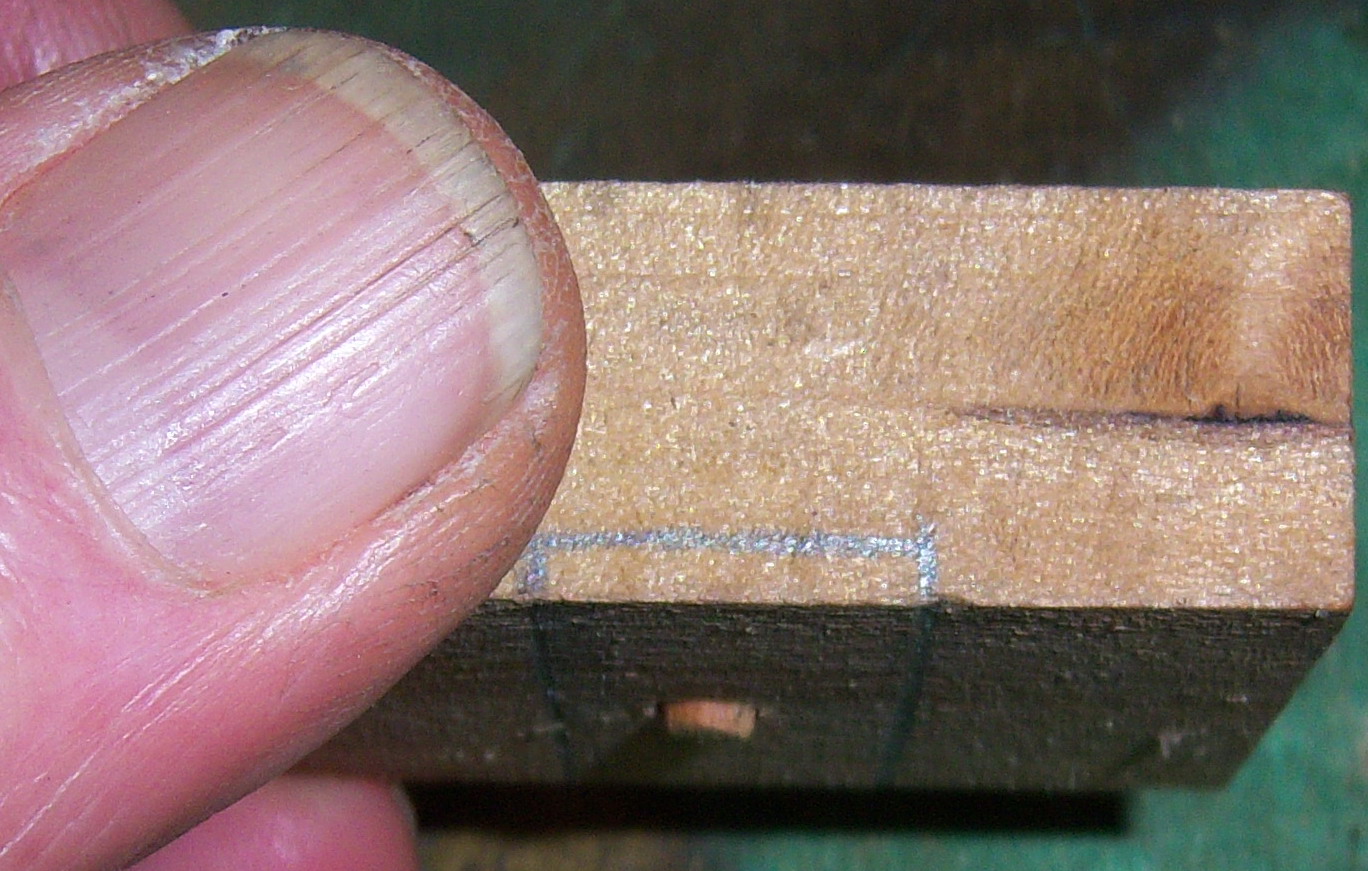

The assembly jig

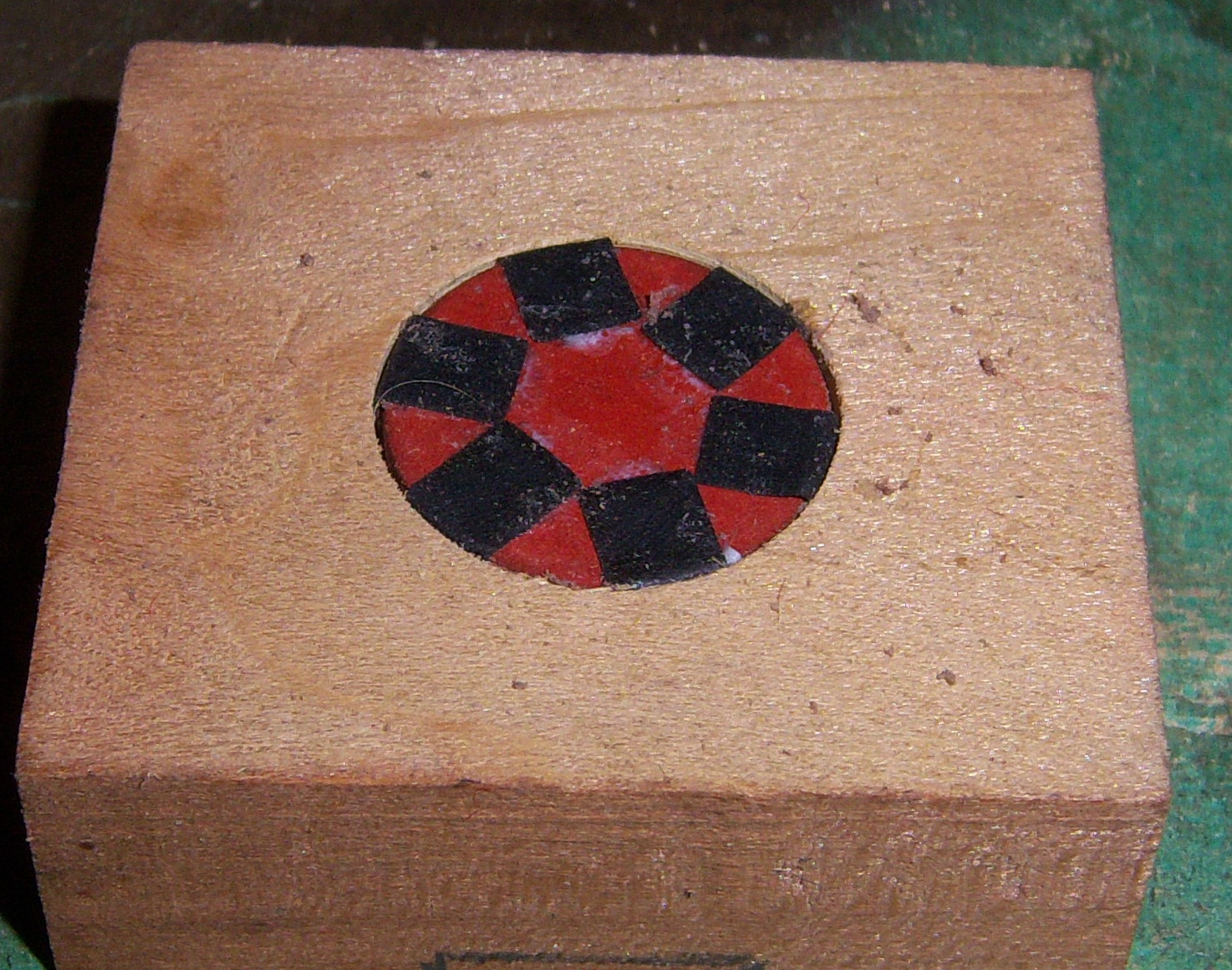

Gluing the felt to the hard disk

Placing the parts in the jig

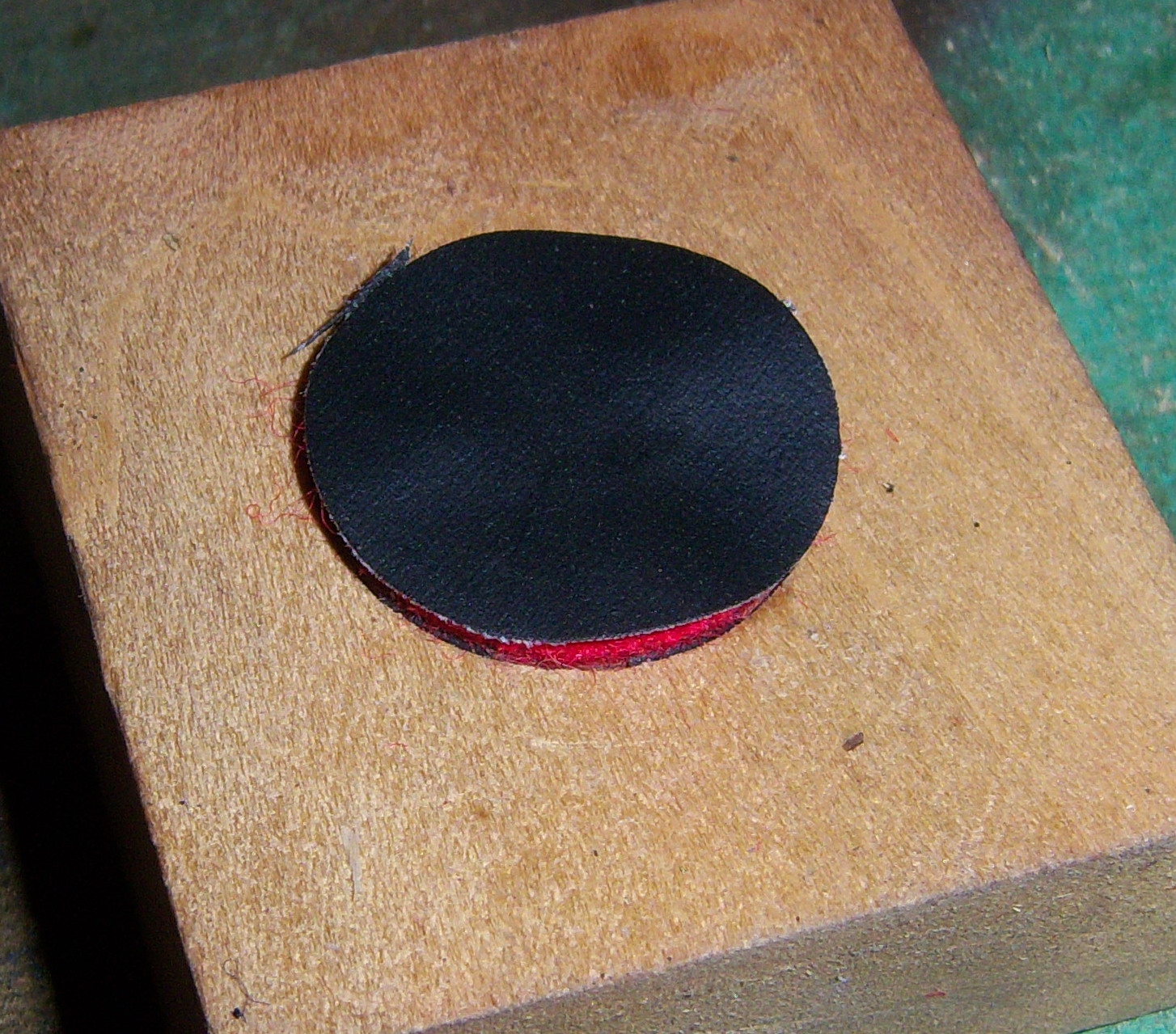

Facing glued to hard disk

Applying glue to the stem

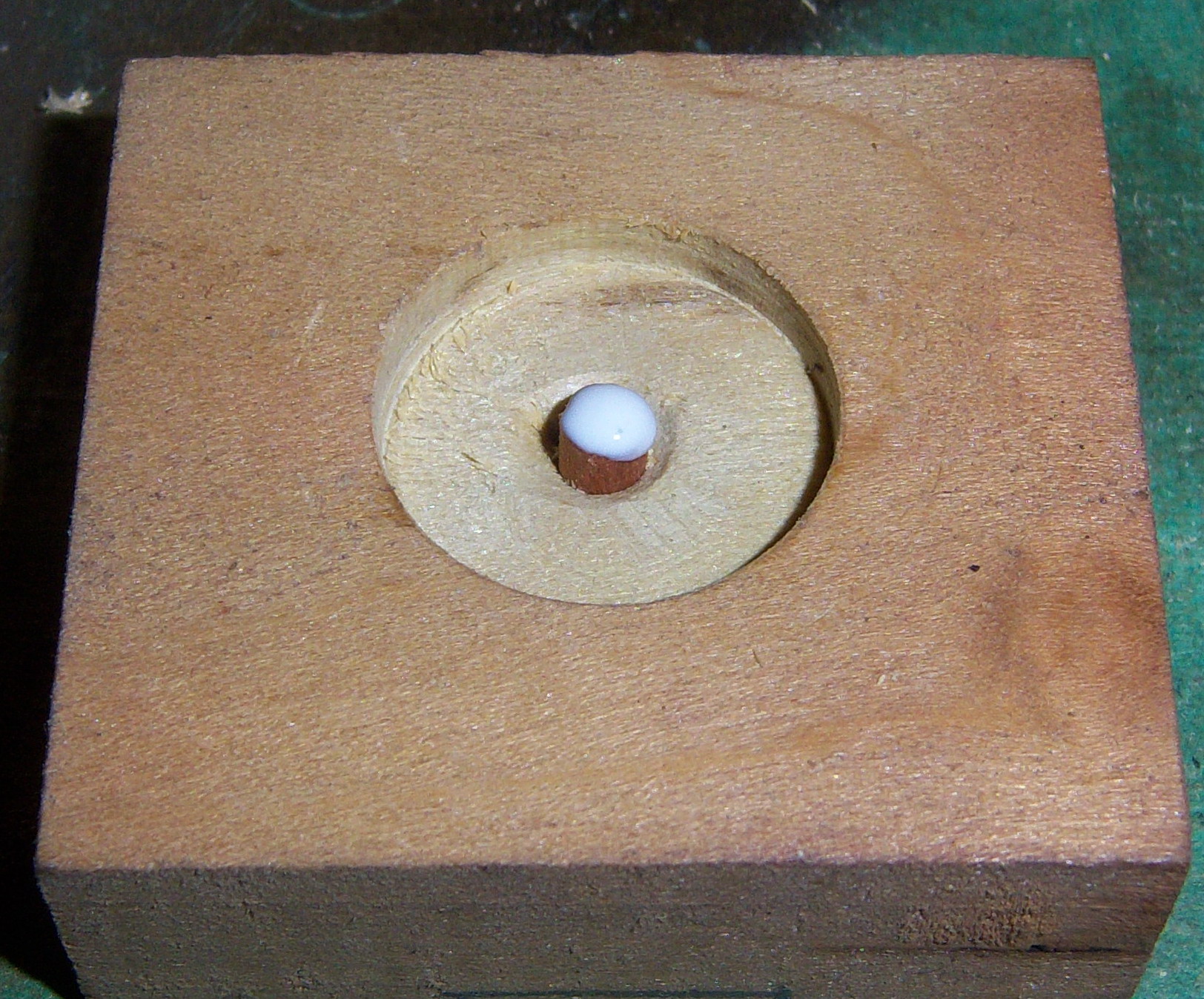

Spacing the valve from the top

Spacing the stem from the bottom

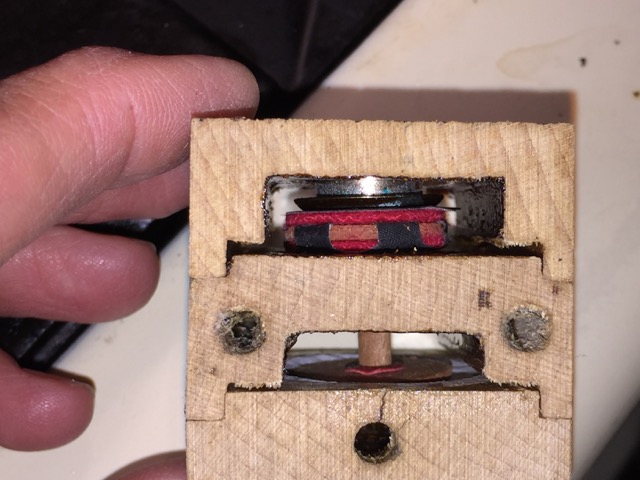

Intake side of valve completed

Applying glue for the exhaust facing felt

Placing the felt for the exhaust facing

Glue for exhaust facing

Placing the exhaust facing

Completed Valve

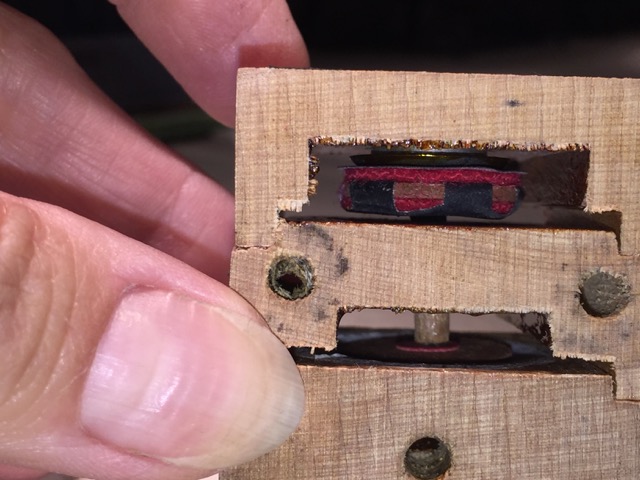

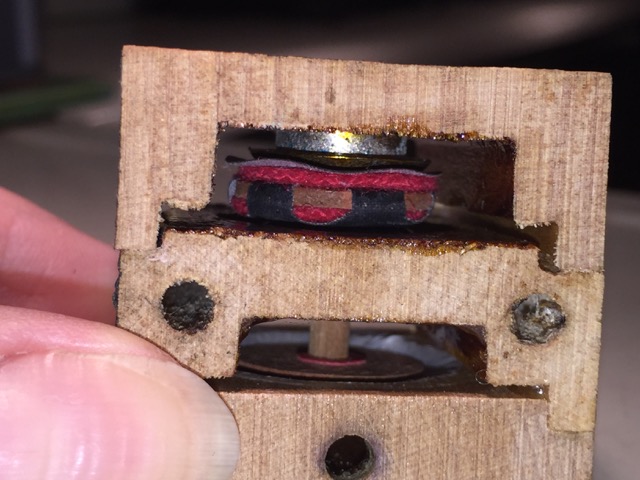

In the photos of the first and third block, it looks like the upper valve seat slipped down during the dismantling process. Compare the position of the seats in 1 & 3 to the position of the seat in #2. Obviously a big difference. The seat in #2 looks to me to be in the correct (or normal) position, but the stem is so long that the valve isn't resting on the inside valve seat.  Valve Block #1

Valve Block #2

Valve Block #3

All valves MUST rest on the inside seat when at rest. This should be checked before the upper section of the block is glued in place. To insure that the stem is not too long, I look for a tiny (0.010") air gap between the bottom of the stem and the lifter disk. If there is too much of a gap, you can glue a tiny circle of tan pneumatic leather to the bottom of the stem. Regarding the position of the upper valve seat, I use a 0.030" thick paper disk. I put the disk on top of the valve and then put the upper section of the block in place. Then I look to see if the upper section of the block is resting where it will be glued to the block. If it looks like the upper section is lifting, I move the upper seat upwards. This can be a little challenging. I use a very small hammer to 'tap' the seat upwards. Then test again until it's right. (I also use a standard .030" metal feeler gauge to test the valve clearance. If I feel any resistance as I slide the gauge between the seal and the valve, I move the seat. If it's 'sloppy' [too much clearance], I move the seat.) Moving the seat 'down' (to reduce the clearance) can be a bit harder than moving it up because there's really nothing to 'bang on' (from the top). So, I use a screwdriver and gentle pry the seat down from the inside, being careful to keep the seat parallel with the top of the block. After the seat is in the correct place, you'll need to seal around the top edge of the seat with shellac. Do this before gluing the section in place. |

![]() ..To

The Top of this Page . . . . . . . . . . .

..To

The Top of this Page . . . . . . . . . . . ![]() ..To The HOME Page

..To The HOME Page

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |