|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

|

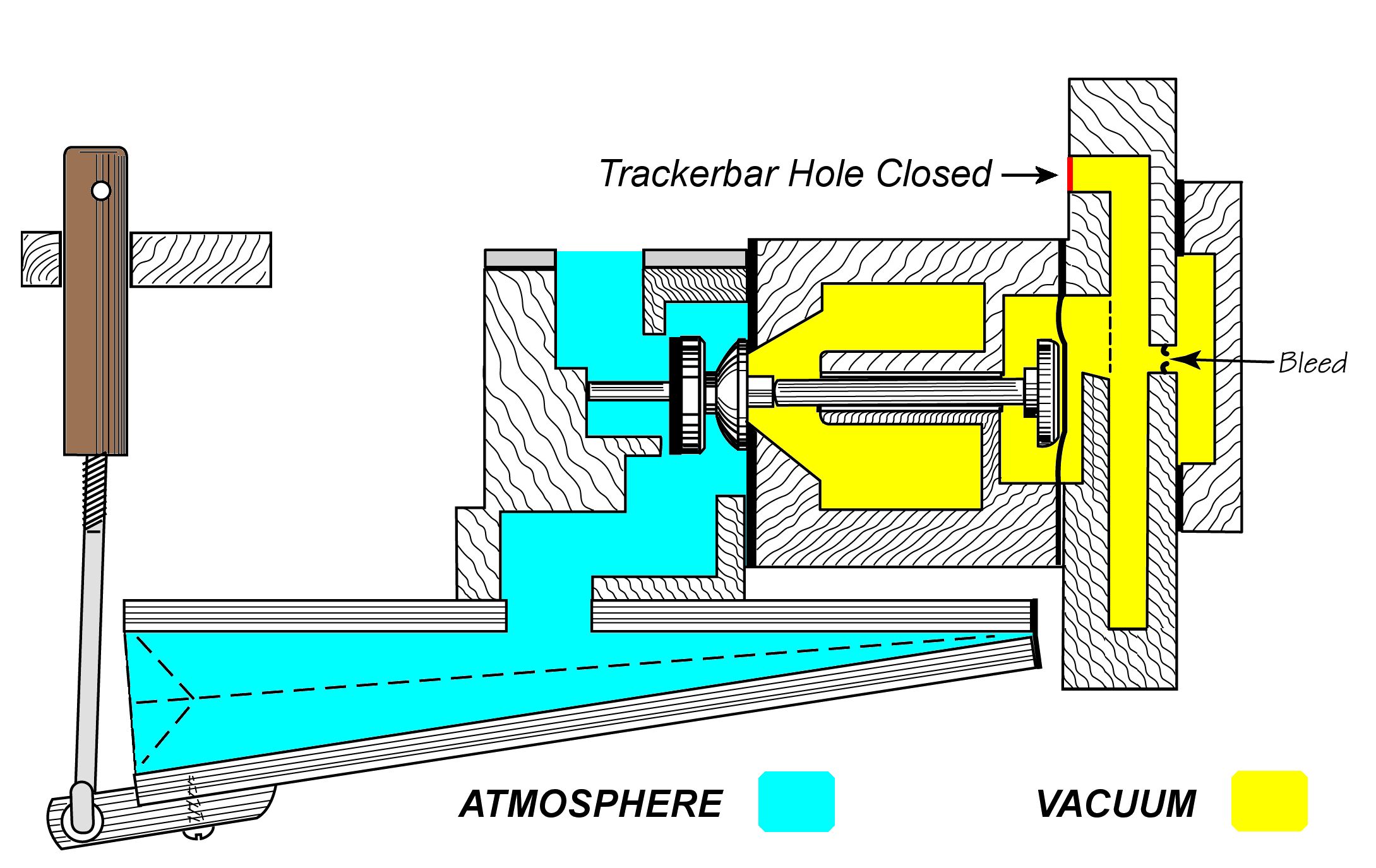

While there is no argument about the fact that it is vacuum which makes the player piano work, it is the bellows which uses and creates that vacuum. The average player piano contains one hundred bellows of various sizes and each bellows has its own job. In order to operate correctly, every bellows must be air-tight. Also, every bellows works together with a valve of one sort or another. Since Chapter 1 dealt with the note, or poppet, valve it seems appropriate to continue with the note bellows, or striker pneumatic. In the drawings below, the bellows is mounted on a "wind chest" which acts as a channel between the valve assembly and the bellow. Typically, the bellows would be mounted on the underside of the wind chest but for purposes of explanation and ease of understanding I have placed it on top. Referring to Figure 8, when the pouch rises, it pushes the valve (in red) up and closes off the exhaust port. Now that the basics have been explained, lets look at how this really happens. In the below graphic of a Pratt-Read system, we see all of the parts mentioned previously plus the striker finger and the pushrod, which pushes on the piano action to make the note Play. Also, you see the channel that leads to the trackerbar. To see the valve in action, click here

In the above graphic, which shows the bellows in the closed position, note the 'reduced atmosphere' area. This area is marked as 'reduced' because of the 'vacuum' which passes through the 'bleed'. While the function of the bleed was discussed in Chapter 1, a few more details should be presented. First, let's consider what would happen if the bleed was to become clogged or closed off althogether. Would the valve change state when the hole in the trackerbar 'opened'? Yes, it would! In fact, it would change state very quickly! That's because the full force of the atmosphere would enter into the pouch well and the pouch would 'puff up' almost immediately. However, what would happen when the hole in the trackerbar 'closed'? Now, there would be little-to-no vacuum to equalize the pressure in the pouch well and the valve would stay 'on' until the pouch relaxed. (This is a relatively common problem in players that are not well maintained. More information about keeping the bleed clean is presented here.) Now let's consider what would happen if the bleed was to big. In reality, this can't happen unless someone physically changes the bleed cup. However, there is another way for vacuum to get into the pouch well, and that's 'through' the leather pouch. This is a relatively common problem in both older player pianos and players where the pouches have been replaced during a rebuild. In older players, the leather loses it's air-tight quality as it dries out and/or becomes worn where it flexes. In rebuilt players, the leather is not as air-tight to begin with because the animals that are raised for their leather and the tanning process used to prepare the leather are not specialized like they were during the heyday of player pianos. The result, in both cases, is that the leather 'leaks', and that leakage is exactly the same as a 'bleed'. But how does all of this relate to performance? Simply put, if there's too much 'bleed', the valve will be slow to come 'on' when the hole in the trackerbar is 'open' and fast to turn 'off' when the hole in the trackerbar is 'closed'. Conversely, if the bleed is too little, the valve will be fast to come 'on' when the hole in the trackerbar is 'open' and slow to turn 'off' when the hole in the trackerbar is 'closed'. So, as you can see, the bleed has a lot to do with the optimum performance of the valve. With regards to the striker bellows, there are three critical measurements; the length, the width, and the span. All three were engineered when the system was created to work in coincidence with the valve. So, it would be unwise to change any of the parameters when rebuilding the bellows. Information about removing, cleaning, and recovering the striker pneumatics can be found at Player-Care on these pages: Removing, Cleaning, and Recovering

|

![]() ..To

The Top of this Page . . . . . . . . . . .

..To

The Top of this Page . . . . . . . . . . . ![]() ..To The HOME Page

..To The HOME Page

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |