|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

Standard |

|

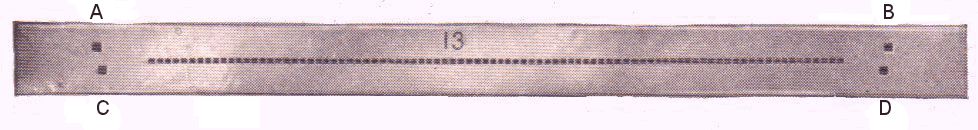

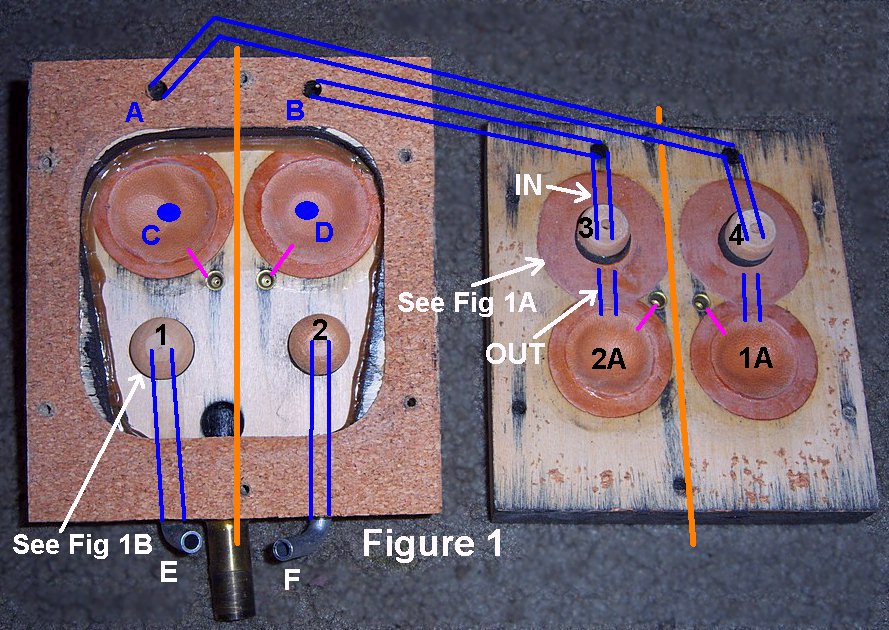

Before you can understand why a standard 4-hole tracker isn't working properly, it is imperative that you know how the valves function. Referring to Figure 1 (below), you see two sets of identical pouches and valves. Also, Figures 1A and 1B give you a look 'inside' the two 'control' valves. Like most control valves in a player piano, they will be turned either 'on' or 'off' by a signal from the trackerbar. However, unlike most valves in a player piano, these valves work in 'conjunction' with each other. To understand how this is accomplished, we will examine various 'conditions'. Let's get started. (For purposes of this explanation it is assumed that the tracking bellows are correctly aligned. See Testing the Tracking Device). Also note that holes A and B are connected to the outermost trackerbar holes on the left and right respectively. Holes C and D, which are under the pouches marked C and D are connected to the innermost trackerbar holes on the left and right respectively. Below is a logic chart of what happens when the holes are open or closed. For a more detailed explanation, see Pages 143-145 of the book 'Player Piano Servicing & Rebuilding' by Arthur Reblitz.

Roll Tracker Logic Chart

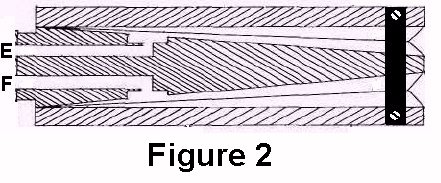

Condition #1: (*Unusual) All four tracker holes are 'open'. (*This is an unusual condition because it would mean that the music roll is less than 11-1/8" wide. The normal roll is 11-1/4" wide.) In this condition, pouches C and D are inflated which applies pressure to valves 4 and 3 respectively, thus preventing atmosphere from entering pouches 1A and 2A, which keeps valves 1 and 2 in their deactivated state. Now, what's important to note is that when valves 1 and 2 are deactivated, vacuum is being supplied to their respective bellows (via ports E and F). And, with an equal amount of vacuum in each bellows, they 'self-center'. See Figure 2 (below).

Condition #2: (*Normal) The two outermost tracker holes are 'open' and the two innermost holes are 'closed' -covered by the paper music roll. (*This is considered the normal condition because there is exactly 11-1/4" between the inside edges of the two outermost tracker holes. And again, the normal roll is 11-1/4" wide.) In this condition, pouches C and D are relaxed and there is no pressure being applied to valves 4 and 3 respectively. This allows the atmosphere at A and B to enter the 'IN' port of valves 4 and 3, where it can continue 'OUT' to pouches 1A and 2A respectively, causing them to inflate. When they inflate, they push valves 1 and 2 'on', which turns the vacuum to ports E and F 'off'. And, with no vacuum in either bellows, the bellows will stay where ever they were when the vacuum was turned 'off'. Typically, the bellows will be 'balanced' as in Figure 2 (above).

Before continuing with the next four conditions, it's relevant to introduce you to two 'forces' that effect the operation of the tracking system. They are the coil spring in the upper left roll chuck and the outward pressure 'V' spring that's attached to the upper tracker bellow. Both springs serve a dual purpose. The primary purpose of the coil spring in the upper left roll chuck is to hold the music roll in place. It's second purpose is to apply pressure to the tracking cam so the music roll will follow the movement of the cam. The primary purpose of the outward pressure 'V' spring that's attached to the upper tracker bellows is to keep the bellows from falling downward (because of gravity) when the music roll is removed from the spoolbox (See Note 1). It's second purpose is to counteract the pressure being applied to the tracker cam by the coil spring in the upper left roll chuck. These opposing pressures reduce the amount of effort that's required to move the tracker cam. Unfortunately, no real effort was ever made by Aeolian to insure that the two springs were in balance with each other. As a consequence, it's relatively common to see trackers where the bottom bellows is almost full closed while the top bellows is almost fully open, which can cause another problem (see Note 2) Condition 3: (Tracking narrow rolls) A narrow roll is one that is between 11-3/16" and 11-1/8" wide. Generally speaking, if a roll is less than 11-1/8" wide, it will not track faithfully. Condition 4: (Tracking normal rolls) A normal roll is no more than 11-1/4" wide. Condition 5: (Tracking wide rolls) A wide roll is one that is no more than 11-3/8" wide. Generally speaking, if a roll is wider than 11-3/8" wide, it will not track faithfully. Condition 6: (Rolls with rips) 'Believe it or not', the 4-hole tracking system does a pretty good job when it comes to tracking rolls with rips, tears, or missing sections at the edges. Here's why.

Note 1: One of the most common problems with horizontally inclined tracking bellows has to do with what happens to the bellows cloth as it ages and where the bellows 'rest' when the player isn't being used. Unfortunately, it took a number of years for Aeolian (which made 'modern' players from 1964-1986) and Standard (which made players between 1904-1931) to realize the need for a 'helper' spring that would 'center' the bellows when the system wasn't operating (or 'at rest'). The reason it was important to center the bellows when the unit was at rest is because all bellows cloth 'takes a set' as it 'stiffens' with age. If, over time, the cloth stiffens such that one bellows is open or closed more than its partner, the tracker system will be permanently out of alignment. This is because the tracking system is designed such that applying an equal level of vacuum to both bellows at the same time is suppose to center the bellows, and if the bellows cloth is 'set' such that it takes more energy to move the bellows to center in one direction than it does to move it in the other direction, the mechanism cannot operate smoothly, and the music rolls will track erratically or poorly.

If the cloth is stiff but otherwise still in very good condition, i.e. airtight, here's a quick fix that I've found works very well. Simply wet the cloth with water and secure the bellows into a position that is 'opposite' of where they were until the water dries. If they are still 'unbalanced' after the first wetting, wet them again and secure them in a position that is further 'opposite' from where they were when at rest. While this procedure will not appreciably reduce the stiffness of the cloth, it will help equalize the amount of effort (or vacuum level) required to keep the bellows centered when in operation.

Also, as I have been telling all of my customers who have units with horizontally inclined tracking bellows, "Always keep a music roll in the spoolbox. This will keep pressure applied to the tracker cam which in turn will keep the tracking bellows in their 'normal' operating position" -which is typically 'centered' (if the device is working correctly).

Note 2: Besides the problems mentioned in Note 1, there is another problem that is potentially more distressing that can, and often 'does' occur when the tracking bellows are out of balance. Most simply stated, the problem is that the rolls might rip during the Rewind cycle. The reason this can happen is because there is no vacuum applied to the tracking device during Rewind. And even if vacuum was applied to the tracker during Rewind, the roll is moving so fast that by the time it could react to an error in the position of the paper, that error is long gone, and the tracker will 'introduce' an error where one didn't previously exist. (This is the main reason why the tracker is disabled -or turned 'off'- during Rewind.) Here's how it happens. During the Play cycle, the tracker is constantly struggling to overcome the imbalance in the relative position of the tracker bellows, and it might even do a fairly good job at keep the roll 'on track'. Then, the unit is shifted in Rewind, the vacuum to the tracker is turned off, and the tracker bellows move back to their 'unbalanced' position -or what I call their 'comfort zone'- and the music roll moves left or right a small amount. The problem is, all of the paper on the take-up spool is now in one horizontal location and the music roll is somewhere else. In other words, they are no longer in alignment with each other. And, since the distance between the two roll flanges is established by the width of the paper, there is no 'extra' room for the paper that is now, so to speak, 'over the edge'. When the music roll paper is relatively 'young', it will usually 'adapt' to this misalignment, and the result will be that the edge of the paper will get 'curled' upwards. (See Tracking Problems -Curled Edges). Older paper is not so forgiving. It too, like bellows cloth, is getting stiff or brittle with age, and since it can't 'adapt' to the misalignment, like young paper can, it simply starts ripping at the edge. This ripping occurs so rapidly that's it's almost impossible to stop everything fast enough to prevent the roll from incurring fatal damage. So, is it important to make sure that the tracking bellows are 'balanced'? I'll let you be the judge.

For more information about music roll tracking devices -click here.

|

![]() ..To

The Top of this Page . . . . . . . . . . .

..To

The Top of this Page . . . . . . . . . . . ![]() ..To The HOME Page

..To The HOME Page

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |